Our family started making masks for healthcare workers shortly after the Shelter-in-Place order went into effect. It all started when I read stories about doctors and nurses all over the country who desperately needed masks.

The military spouse in me prompted me to look at what we had on hand to see if I could make my own masks. The required materials are actually quite simple: cotton fabric, non-woven interfacing, and elastic.

Luckily for us, it turned out that we already had a box of 100% organic cotton designer fabric from this cute little boutique in Berkeley that I bought years ago. We also had the Pellon, which is a non-woven interfacing layer that helps stabilize the dress and the fabric. The Pellon acts as a layer of filter that closely resembles that of a medical-grade N95 mask. Lastly, we had some elastic bands from when I learned how to sew and tried my hand at making pajama pants!

I rallied the girls and our family and we got started.

Becoming Mask-Makers

I reached out to a friend of mine who had started to make masks in New Orleans with her mom. She gave me a template, answered some questions, and we went to work.

My 4-year-old cut the fabric, my 8-year-old pinned the fabric together, my husband ironed the fabric together, and I did the sewing and putting them together. My mom and sister also helped us out.

After four hours, we had completed eight masks.

I posted this story on Facebook with the intention of dropping the masks off at our local hospital here in Walnut Creek. However, I woke up the next day to a message from a Florida doctor who wanted to purchase all of them. I also had a donation for $100 for the masks, and I had only made eight.

While I felt excited that people wanted what I was making, it was bittersweet. It saddened me to realize that doctors found themselves in such a desperate situation that they were willing to pay a complete stranger across the country for masks. I learned that doctors wanted homemade masks to wear over their N95 masks to prolong their wear.

We had other people who reached out as well. There was a local physical therapist, a Whole Foods cashier, and a clinical psychologist at Kaiser, all unable to get their hands on the masks they needed to protect themselves and their clients.

Hearing these stories broke my heart, and by the next day, we had made 16 more masks. It was a really difficult decision to decide who got masks first. Who needed them most? Was it the doctors and nurses fighting on the front lines or the cashier exposed to hundreds of people each day?

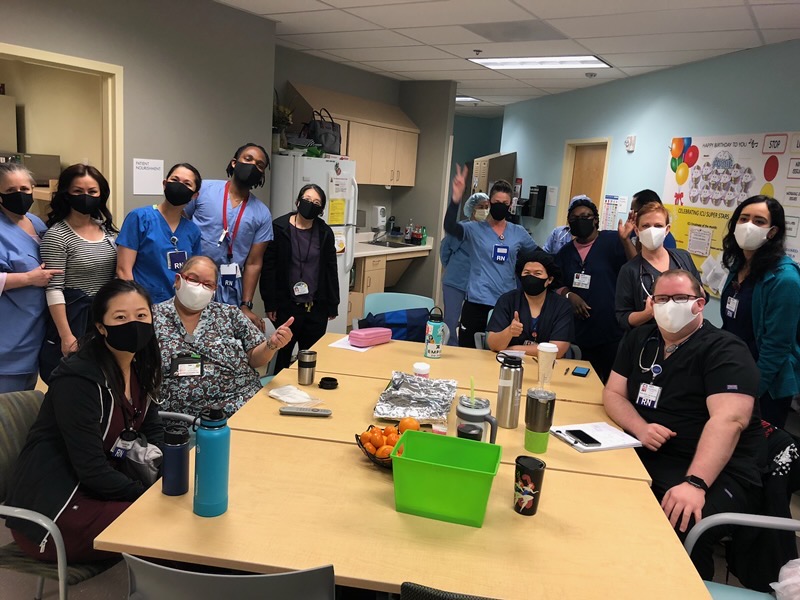

Here is what we decided: We donated half of the masks to John Muir Walnut Creek Hospital and we drove the rest down to our friends, family, and real estate clients who reached out. My husband, Tim, and I did drop-offs for a couple of hours. On the drive back, the reality of how big of a problem this is hit me hard. I broke down emotionally, realizing that my 16 masks were just a drop in the bucket.

Growing Our Reach

Making masks is not actually my area of expertise, but getting people involved in big, important projects that make a difference is. I started to think about the doctor in Florida and the nurse in Pennsylvania who reached out. Were there other mask makers geographically closer to them? How could I help connect people who needed masks to those in their area who make them?

I reached out to my military spouses, and what we have now is a modern Rosie the Riveter movement. Military spouses are just wired a different way from the rest of the world. We activate when our soldiers are in harm’s way and they need our help. In this case, our soldiers are the doctors, nurses, pulmonary specialists, and all of the frontline workers.

Together, we banded together and started a non-profit called We Have Masks. We Have Masks gets masks to those that need them the most. One hundred percent of donations go towards purchasing professional-grade N95 and surgical masks, material supplies for sewing the cloth masks, and filters for the pocket-style cloth masks. Our mission is to deliver masks to frontline heroes at no cost to our makers or those receiving the masks.

Since We Have Masks was launched on March 22, over 5,000 manufactured masks and hundreds of community sewn cloth masks have been shipped all over the United States.

Mask-Making Instructions

The simplest elastic mask is the Deaconess mask, and we have instructions on how to mass-produce them that you can follow. You can also make one mask at a time.

Froedtert design is a mask with ties you can make at home. I see this design most often.

If you need masks, would like to donate masks, or would like to make a donation, please visit our website.